Welcome to Our Company

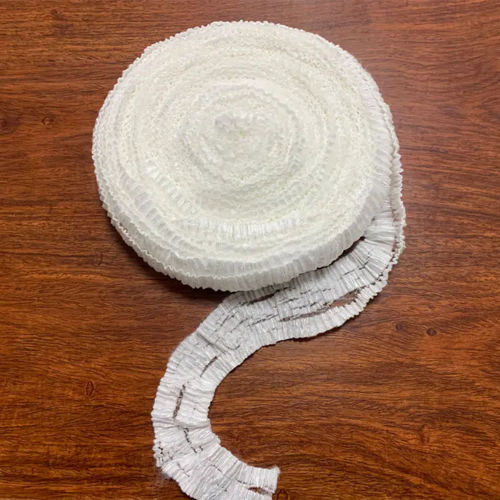

PLA Cigarette Filter TOW

9 USD ($)/Kilograms

Product Details:

- Type PLA

- Material Others

- Other Material PLA

- Style Flame

- Size As per requirement

- Quantity As per requirement Container

- Gas Use Flame

- Click to View more

X

PLA Cigarette Filter TOW Price And Quantity

- 14500 Kilograms

- 9 USD ($)/Kilograms

PLA Cigarette Filter TOW Product Specifications

- PLA

- Smoking

- As per requirement

- Flame

- Flame

- Others

- PLA

- As per requirement Container

- PLA

PLA Cigarette Filter TOW Trade Information

- Shanghai

- 10000 Kilograms Per Month

- 25 Days

- Yes

- Free samples are available

- 200 KG Carton

- All India

- D&B

Product Description

- PLApolylactic acid fiber commonly known as corn fiber uses high optical purity Lpolylactic acid PLLA as raw material uses its high crystallization and high orientation characteristics through different spinning processes melt spinning wet spinning dry spinning spinning drywet spinning electrospinning etc Polylactic acid is derived from corn cassava straw etc

- As a new green fiber PLA fiber is different from traditional cellulose fiber and chemical fiber but it has the advantages of these two fibers at the same time

- On the one hand its raw materials like cellulose fibers come from natural plants

- On the other hand PLA fibers have the same superior fiber properties and processing properties as chemical fibers and have various effective functions and relatively stable melting points At the same time they can also be made into various functional PLA fibers for occasions with special requirements

- Biodegradability

- PLA Tow is made from biodegradable polylactic acid PLA fibers Compared to traditional synthetic fibers it has better decomposition properties in the environment reducing its impact on the environment

- Renewable resources

- PLATow is derived from renewable plant resources such as corn starch It has a lower carbon footprint and environmental impact compared to petroleumbased fibers

- Excellent filtration performance

- PLA Tow have high porosity and surface area effectively capturing and adsorbing harmful substances and particles in tobacco smoke It helps reduce the levels of tar nicotine and other harmful substances in tobacco smoke

- Odorless and low volatility

- PLA Tow is free from harmful chemicals or volatile substances unlike traditional synthetic fibers This allows it to avoid releasing unpleasant odors and provide a purer and fresher smoking experience Additionally PLA Tow emits fewer gases during use due to its low volatility and stability which reduces adverse impacts on air quality and potential risks to human health and the environment

- High customization

- PLA Tow can be customized for different characteristics of cigarette filters by adjusting parameters such as fiber density length and diameter This includes regulating the resistance adsorption performance and smoke purification effect of the filter This tunability allows PLA Tow to meet the specific requirements of different smokers in terms of filter performance

- Excellent Strength and Durability

- PLA Tow is excellent strength and durability stem from its molecular structure and processing techniques It possesses high crystallinity and strong intermolecular bonding allowing for effective stress transfer and load dispersion Special processing techniques such as stretching and thermal setting further enhance its performanceAs a result BMC PLA Tow exhibits high tensile strength wear resistance and longterm stability

- PLA Tow for Cigarette Filters was developed for smokers who prefer the convenience of a filter This biodegradable filter material ensures full taste neutrality and delivers an exceptional smoking experience

Enter Buying Requirement Details

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Call Me Free

Call Me Free